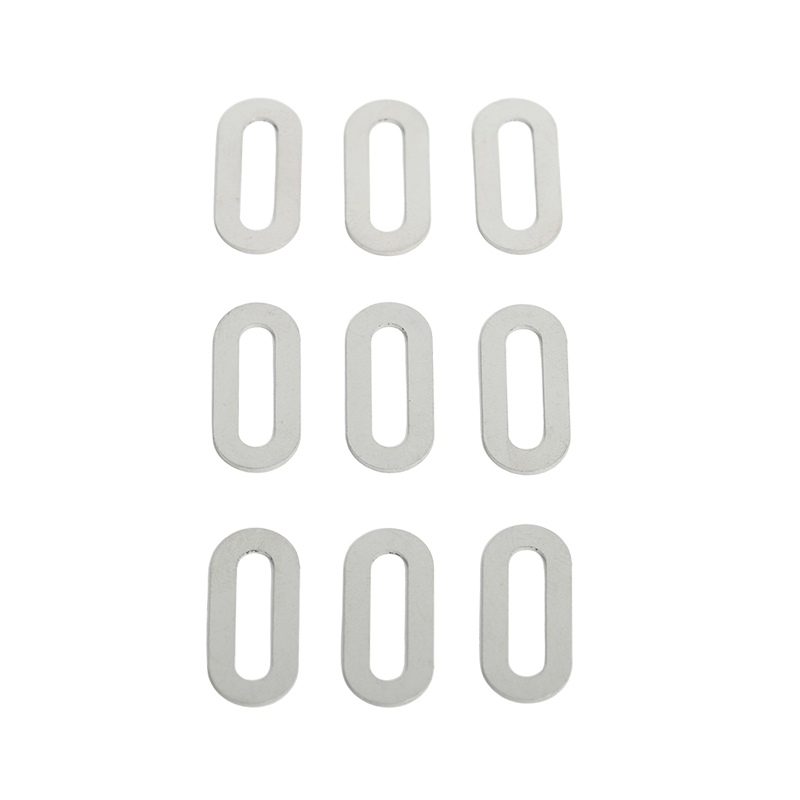

In the internal structures of mechanical assemblies, piping connections, electrical installations, and even precision instruments, there is a crucial yet often overlooked component—304 stainless steel small gaskets.

- +86-13828733192

- hxsmtgp@163.com

- No. 49, Baigongao Industrial Zone, Qiankeng New Village, Qiankeng Community, Fucheng Street, Longhua District, Shenzhen 102