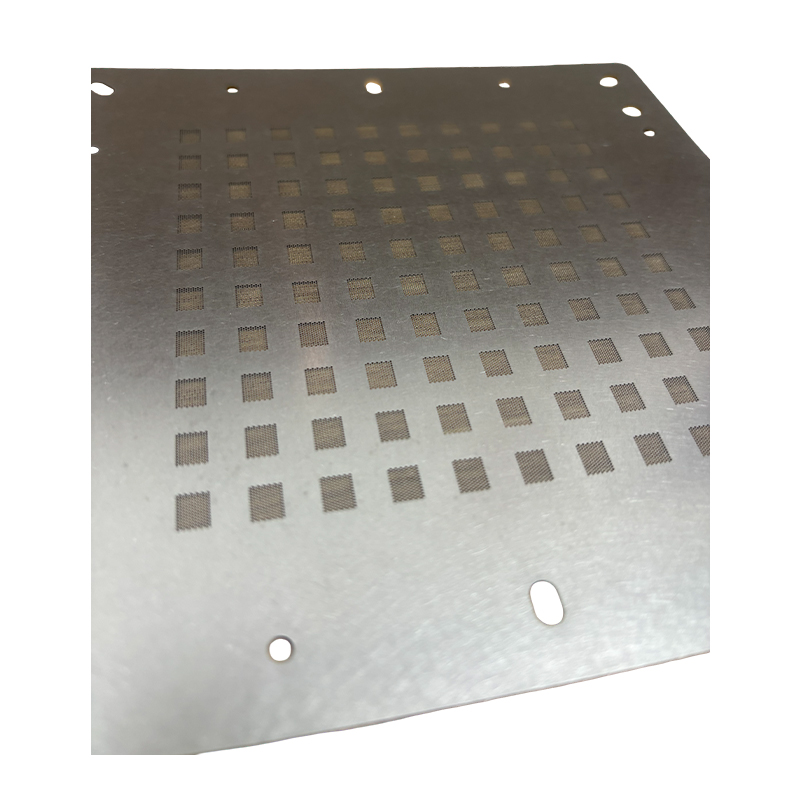

In the trend of increasingly thinner and more integrated modern electronic devices, miniaturization and functional integration of internal structural components have become key challenges.

- +86-13828733192

- hxsmtgp@163.com

- No. 49, Baigongao Industrial Zone, Qiankeng New Village, Qiankeng Community, Fucheng Street, Longhua District, Shenzhen 102